If you do not have edging installed around your driveway, you run the risk of accidentally going off the driveway. This issue can be avoided entirely by installing a curb, which serves the function of a buffer between the surfaces. But, how do you build a curb if you haven't got one? We've found the answer.

Concrete with cement is the most common material used in curb construction. Other common materials for curb construction include asphalt, stone, and masonry blocks. To build a curb for a driveway you should follow this procedure:

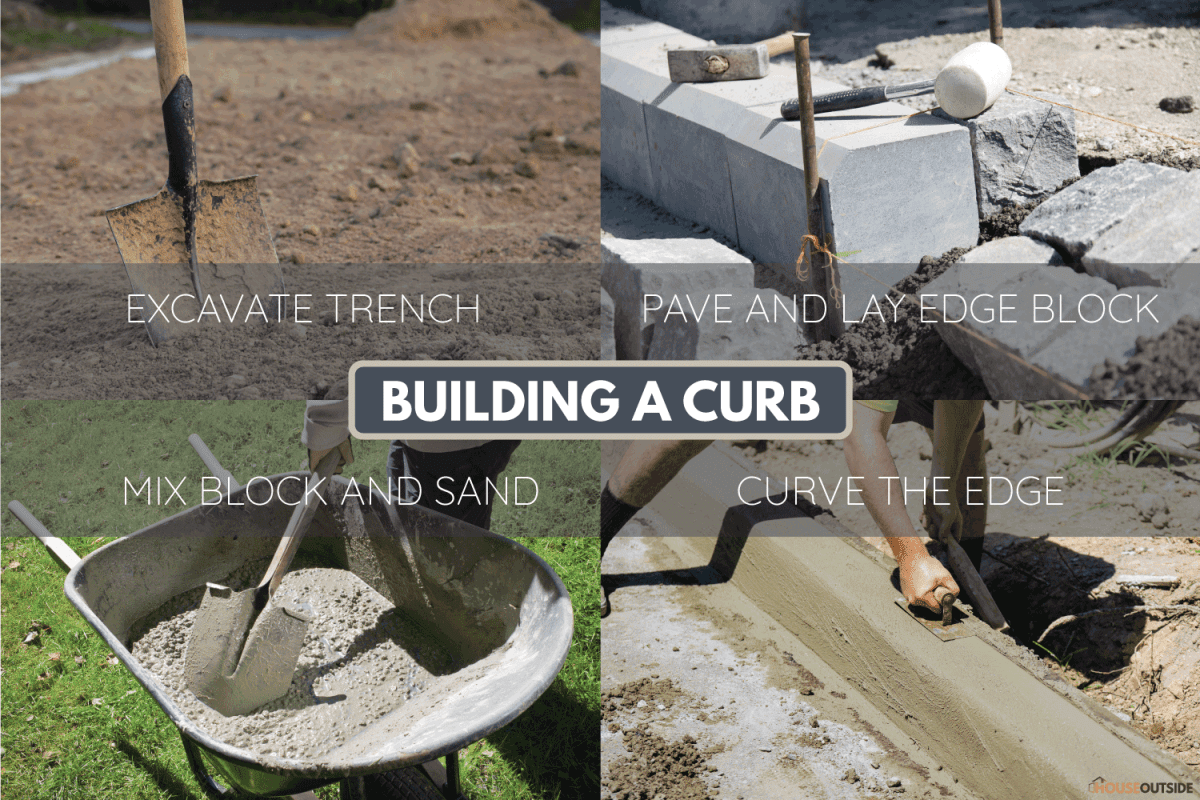

- Excavate trench

- Mix block and sand

- Pave and lay edge block

- Curve the edge

Keep reading to get the step-by-step procedures on how to build a curb for your driveway and the best concrete to use.

What is a Curb For Driveway?

The driveway curb is a specific cutout part of the sidewalk that allows vehicles to enter the driveway to the residence from the main road surface. Most suburban neighborhoods contain concrete sidewalks with elevated curbs.

This provides a place for walking and decreases water runoff during rainstorms. A standard driveway will require occasional maintenance. This is due to damage generated by weather in various locations and wear and tear created by normal usage of the driveway.

Most gravel driveways will require new gravel every few years. Concrete and asphalt driveways require periodic patching and crack elimination. The driveway curb should also be maintained with the general driveway area.

What Is a Mow Curb?

The mow curb is the edge of the sidewalk or pavement that is made to serve as a barrier. However, there is no specific concrete utilized for it.

Curbs are made from a variety of materials, including asphalt, stone, and masonry blocks, but Portland cement concrete is the most common material. The type of material is dependent on the purpose and budget.

How Do You Build A Curb For A Driveway?

Here is a ">procedure for building a curb for a driveway:

- Excavation of Trench: Make sure the trench can hold your edging block and 75mm of cement.

- Mixture: To secure edging blocks, mix sharp sand to cement in 4:1.

- Laying: Trace your edging with a taut string. Before putting blocks, cement this line.

- Use a paving mallet to secure and level edge bricks for your driveway, patio, or path.

- Create a 75mm-wide haunch on your edging block. This will hold your driveway, patio, or pathway in place.

- Unsupported edging bricks increase the chance of driveway damage.

- Halfway up the edging block should be supported; finish the support so that it is covered and aesthetically pleasing.

- Curves: Check curved edge height using a spirit level and the taut line.

- Curved edgings may require cutting blocks. Lay out your edging and mark the block with chalk.

- Use a saw or block splitter to cut the blocks to form. From this point, lay like a curved edging.

- Creating an arc creates a curved edge easily. To do this, determine the central point on the proposed paved area and plant a stake in the ground. Use a single string from this stake to measure out each block to produce a uniform curving border.

- Flat-top path edging: Flat-top path edgings separate paved areas from garden soil or turf and keep vegetation off the walk or patio. Flat top edgings come in three heights, 150mm, 200mm, and 250mm. Place these edges on a 100-150mm bed of concrete and haunch three-quarters of the way up the outside.

What Concrete Do You Use For Curbs?

There are differences between the various kinds of concrete. In the realm of construction, there are literally thousands of distinct varieties, each of which is employed for a specific purpose.

Concrete is the most prevalent type of concrete, and sidewalks made of concrete are extremely widespread. Ready-mix concrete is the type of concrete that is most commonly used for constructing concrete sidewalks, curbs, slabs, and driveways.

Thickness

In terms of thickness, a depth of four inches is considered standard. This thickness is in addition to a base of gravel, sand, limestone, or some other aggregate measuring between two and three inches.

Driveways, curbs, slabs, and sidewalks made of concrete are required to have a minimum strength of 4,000 pounds per square inch (psi) after a curing period of one month; however, 4,500 psi is considered to be the industry standard.

Do Concrete Curbs Need Rebar?

Rebar is something that contractors believe should be included in concrete at all times. If you have ever done demolition on reinforced concrete, you will immediately understand why, and at the same time, you will detest the rebar in the concrete that you now need to remove.

On the other hand, you will only be required to do so when the plans specifically call for it; otherwise, using rebar is voluntary. If the appropriate jointing is applied, the use of reinforcing steel in concrete curbs is typically not required and is not advised.

However, if formed curbs are going to be reinforced with steel bars, the bars need to be positioned and fastened within the forms so that they won't be moved while the concrete is being laid and consolidated.

How Deep Should a Concrete Curb Be?

For best strength, the concrete edge should be at least 3.5 inches wide and deep. The concrete edge can be as narrow or as wide as you choose.

The portion of the border that is below grade is what ensures that it will remain firmly in place; therefore, at least two inches of that depth should be below the surface of the soil.

How Much Is Concrete Curbing Per Linear Foot?

Concrete curb installation costs, on average, $6.19 per linear foot in materials, with costs ranging from $5.77 to $6.60 per linear foot. The combined cost of labor and materials is $30.07 per linear foot, with a range that goes from $27.23 to $32.92 per linear foot.

The average cost of a project that is 100 linear feet long is $3,007.43, but the price can range anywhere from $2,722.73 to $3,292.13.

How to Know The Required Concrete For Curbs

It is essential to ensure that you order the appropriate quantity of all supplies, including concrete, when you are planning a building project. If you order too much concrete, you are going to waste money, but if you order too little, you won't be able to finish the project.

The quantity of concrete that is purchased is typically measured in cubic yards. If you have the right formula and are building curbs and gutters, determining how much concrete you will need for the project shouldn't be too difficult.

Calculating The Amount of Concrete

- Step 1: Determine the dimensions of the gutter or curb in terms of its length, width, and height.

- Step 2: To calculate the volume, multiply the dimensions of the object's length, breadth, and depth together.

- Step 3: Divide the gutter's or curb's overall volume by 27 (the number of cubic feet in one square yard).

- Step 4: Multiply the number of cubic yards to get the percentage of spillage that should be allowed for, and add that percentage to the total number of cubic yards.

- Step 5: To determine the total number of cubic yards required for the project, add the spillage allowance.

Can I Pour Concrete Directly On Dirt?

People who have completed a concrete project on their own will tell you that preparation is nearly usually the most challenging element of the process.

If you have spent the time and effort to adequately prepare the work area, the actual process of pouring the concrete is a rather simple and uncomplicated procedure.

However, it is essential to emphasize that you must not pour concrete straight onto the ground before first building an appropriate concrete basis.

The bare minimum of good practice is to do a thorough job of ground preparation by first leveling the subgrade and then compacting it. Then add a subbase of gravel for additional load support of the final slab if needed.

When it comes to the completion of successful concrete projects, having a solid foundation is crucial. If the base that the concrete is being poured over is defective in any way, it is going to have a direct impact on the quality of the product that is produced in the end.

Because of this, it's not always a good idea to pour over the soil. The entire concrete structure will be flawed if even the slightest amount of the dirt base is deformed as a result of the weight of the concrete.

All of this is not to imply that pouring concrete over the soil is impossible, it is perfectly achievable. You can unquestionably achieve achievement in doing so, but you will need to adhere to a particular procedure.

Conclusion

With the right materials and tools, building your curb can be done yourself. Ensure you take precautions with using cement and other tools and ensure it doesn't get damaged or destroyed by pets or kids. A curb is a good addition to the driveway and you cannot go wrong with it.

![Roof Gutter Cleaning Tips. Clean Your Gutters. Gutter Cleaning., Do Gutters Smell? [And What To Do About It]](https://houseoutside.com/wp-content/uploads/2022/10/Roof-Gutter-Cleaning-Tips.-Clean-Your-Gutters.-Gutter-Cleaning.-600x400.jpg)