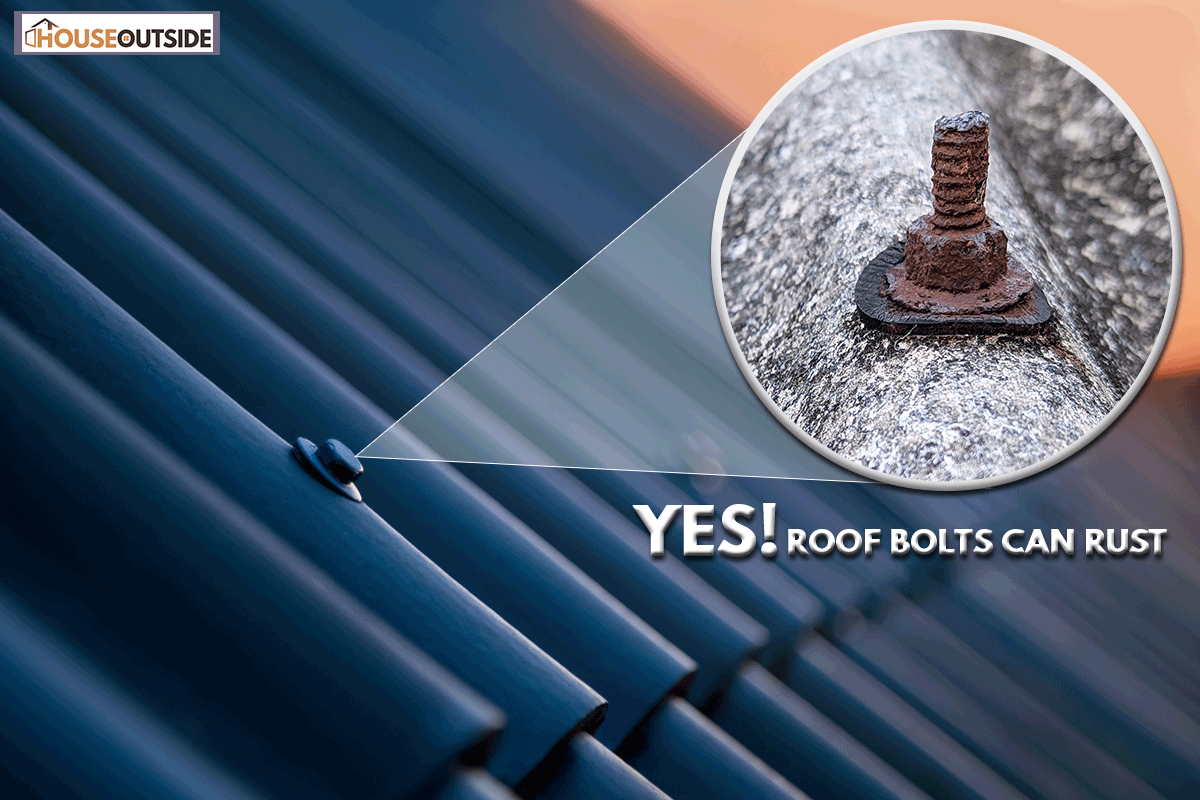

When it comes to the rooftop of a building, extra precautions are needed because that part of the building is always exposed to all elements of weather. Have you noticed your roof bolts rusting or you're wondering if they would rust in the future? This is the answer we gathered after making extensive research.

Yes, roof bolts can rust. Rusty screws on roofs can be caused by airborne acids from industry and chemical sprays, UV radiation from the sun, humidity in tropical or wet places, or salty air. Over a long period, these factors can cause the roof bolts to become rusted.

There are a lot of factors that can cause your roof bolt to rust. Want to know more about roof bolt rusting? Keep reading further to get the detailed information we have gathered for you.

What Are Roof Bolts?

Roof bolts are, as you might expect, generally found on the roof of a building. Because they are on the exterior, they are exposed to the elements. In reality, roofing bolts can be used for a wider range of purposes than roofing.

They are perfect for linking metal to metal, but they also function for other building materials. These bolts have a broad flat head and therefore have a gripping force than a regular bolt. As the stress and strain are distributed along the bolt, material damage is also reduced.

Roofing bolts are frequently fully threaded, which increases their suitability for a variety of uses because they can join thin or thick materials, depending on how far the bolt needs to be inserted.

Do Roof Bolts Rust?

Bolts are made of an iron-based metal, and because they are regularly exposed to rain and moisture, they are likely to rust and corrode.

The degradation of a metal by chemical or electrochemical reactions in its surroundings is known as corrosion. When you hear about bolts rusting on roofs, this is frequently caused by water or other substances from the air.

Oxides that rust expand and take up more space than the initial substance. The pressures involved in this procedure do a great deal of damage to the target structure.

Why Is My Metal Roof Rusting?

Manufacturers have worked hard to create coatings and layering technologies to improve weather resistance for metal roofing and wall cladding. Some even have up to five layers of coatings, each with its special characteristics to withstand harsh environments and warranted up for many years.

Rust, or iron oxide, cannot form without the presence of three substances. These include oxygen, water, and iron. You won't be shocked to learn that water is rust's primary culprit. Any iron material, such as steel, can develop iron oxide, commonly known as rust, when exposed to moisture and oxygen.

Water molecules will enter minuscule holes and cracks in exposed metal even if steel constructions seem solid. Simply dissolved in water, oxygen from the air results in the formation of a layer of rust.

Rust corrosion is an attack that essentially damages the metal because of how it responds to its surroundings. Acidic rain and salty seawater hasten the rusting process. The entire building will eventually collapse and fall apart given enough time. This is a serious cause for concern and worry.

How Do I Keep My Roof From Rusting?

When rust is found on a metal roof, the first step you should take is to remove it. There are numerous strategies to prevent rust in the future.

Painting The Roof

If the roof is painted with a primer that includes at least 80% zinc, a fresh coat of paint can shield the roof from rust and corrosion. Rust can be effectively avoided by using zinc.

Making sure the roof is ready before painting is the best approach to applying a zinc-rich primer. This means that any corrosion and debris on a roof must be carefully removed.

Painting must be done on a clean surface. As a result, dirt cannot get through to the metal roof. It is a smart idea to paint them at least annually.

Use Premium Metal Panels

High-quality metal panels are what you should pick. It's also fantastic if they have some zinc content. You shouldn't utilize subpar metal panels.

Numerous substances contain a surprisingly small quantity of zinc. Your metal panels should include a lot of zinc because it is what safeguards the cut edges.

Galvanized Roofs

By applying liquid zinc to the roof you can galvanize the exposed metal. Since the zinc will provide a layer of protective coating, this will shield the roof from rust and corrosion.

Zinc galvanization will increase the lifespan of the roof. The zinc coating keeps the metal safe and hardens the roof against severe weather including hail, snow, and high temperatures.

Upkeep of The Roof

Once you are aware that rust has damaged your roof, be cautious to prevent more issues. As you would with a new roof, keep the roof clean. To get rid of dirt accumulation, wash it multiple times a year.

If any rust develops in the same or a different location, take the necessary actions to repair and reseal the afflicted areas. Trees that cast an excessive amount of shadow, obstruct sunlight or airflow, or scatter an excessive amount of debris—such as pine needles—onto the roof may need to be cut down.

How Long Should Roof Screws Last?

How many years you get out of a roof screw determines how long it will last. With proper installation and no upkeep, you should get 20 years.

However, you might extend it to 30 years by performing routine maintenance. A screw on a roof may not last as long as it should in some situations, of course.

This can be due to storm damage, bad installation, or poor maintenance. However, as long as you work with a reputable roofing contractor, your roof screws should last.

How Often Do Screws Need to be Replaced On a Metal Roof?

As long as it's your home, a metal roof ought to last. Metal roofs are excellent at deflecting snow, and keeping out rain and powerful winds as long as they are built correctly. But you'll need to watch out that your screws don't lose their seal and come undone.

You should check your metal roof fasteners at least twice a year for any potential screw movement or sealant failures. If you have exposed fasteners, this is very crucial. Make sure that all of the screws and fasteners are tight.

The holes in screws can be forced out by movement. You must refasten the screw if you notice that it is sticking out above the gasket or roof panel and that there may be threads visible. At least twice a year, if not more frequently, look for leaks in your attic

Good sealants are necessary for installing metal roof screws. Around the screws, sealants may deteriorate. Normally, they last for around 10 - 15 years, although roof panels and fastener movement might cause damage. Moreover, the gaskets that are supplied with the fasteners may deteriorate. Examine the component for tightness, fading, corrosion, or breaking.

How Much Does It Cost to Replace Metal Roof Screws?

Because of its durability and strength, metal is a great choice for roofing. Steel and aluminum roofs can last for many years.

The weather and other causes, however, could cause damage to your metal roof that requires repair. Specialists in metal roof repair must be contacted to solve problems including leaks, loose shingles, dents, and rust.

For metal roofs, the cost of replacing the screws ranges from $150 to $1,000. The cost is based on how many screws need to be replaced. In certain circumstances, only a small portion of the roof can require replacement screws.

Do Roofs Made From Metal Leak More Than Shingles?

Roofs made From metal have a higher risk of leaking than shingles do if they are placed poorly. Metal roofs, on the other hand, melt snow and ice to lessen moisture accumulation if you can find a qualified contractor to properly install them.

Because the material is less prone to weather deterioration than other roofing materials, moisture may not leak through your roof.

What Are The Problems With Metal Roofs?

Here are some problems you might encounter if you use metal roofs:

Oil Canning

Oil canning is characterized as a noticeable or wavy distortion of the panels and can happen to any kind of metal. Inadequate handling or storage before installation, stress during the manufacturing process, and thermal expansion and contraction are just some of the factors that can lead to oil canning.

Scratches and Dings

Around your metal panels, life exists. Scratches, nicks, and scuffs that happen as a result of installation, bad weather, or falling objects.

In Summary

Rust can be caused by several factors, ranging from exposure to the elements to chemical sprays and UV radiation from the sun. To prevent roof rusting, coat the roof with zinc coating, use premium metals and maintain your roof.

If you would like to read more about roofs, we recommend these articles: